Reed Wire – Primary Material of Reed

< Characteristics of Dai Seki Reed Wire (HIKINUKI Rolling) >

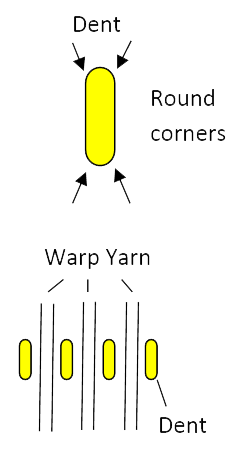

Four Corners of flat wire are all processed to be smooth like capsules.

|

- The R curve is minutely adjusted by each thickness (count of wire thickness) making all four corners round without nail-catching scar, resolving all the problems such as warp yarn cut and yarn friction.

- Straight line of flat wire is very accurate without twist or ripples, causing no friction against warp yarn when used for reed wings.

- By HIKINUKI rolling for thickness and width at the same time, round (original) wire can be adjusted at the appropriate rolling rate to match its material. Because the pressure is even along the line, flat wire does not have any scar or cracking, making very smooth reed wings.

- Each R curve on four corners of flat wire is identical, which reduces friction evenly between wings and warp yarn when formed to be reed wings. This is Dai Seki’s original process invented from various special technologies.

|

|

Table 1

| SUS STAINLESS FLAT WIRE |

| Width (mm) |

Wire No. (#) (s) |

Thickness (mm) |

| 2.2 |

~ # 48 |

~ 0.14 |

| 2.8 |

~ 208 s |

~ 0.12 |

| 4.0 |

~ 314 s |

~ 0.08 |

|

Table 3

| SUS STAINLESS HALF ROUND WIRE |

| No. |

Width (mm) |

Thickness (mm) |

| 1 |

1.80 |

0.55 |

| 2 |

2.25 |

0.65 |

| 3 |

2.75 |

0.70 |

| 4 |

2.75 |

0.85 |

|

|

Table 2

| STEEL (M- 6) FLAT WIRE |

| Width (mm) |

Wire No. (#) (s) |

Thickness (mm) |

| 2.8 |

~ 155 |

~ 0.16 |

| 4.0 |

~ 177

|

~ 0.14

|

|

|